What is Silestone

Silestone is a compound

Silestone worktops are re-engineered from a compound of 94% natural quartz crystals and silica, in a special process and adding polymer acrylic resins, making up the balance of 6% content, to strengthen and improve the original stone, making it more flexible and resilient. The effect of this process is a radiant 3-dimensional crystal-like appearance of which the colour and pattern consistently follows throughout the entire thickness of the worktop.

Silestone is a solid, incredibly hard, dense, non-porous homogenous slab, suitable for stylish worktops in kitchens or bathrooms, vanity tops, countertops, benches, or shower walls. Through a special process Silestone can be shaped into basins, sinks, shower trays, etc making it a designer’s dream.

Quartz is the fourth hardest mineral found in nature, with a score 7 on the Mohs scale, which is topped by diamonds at a score of 10, Corundum at 9 and Topaz at 8. On the same scale Marble scores between 3 and 5, knife steel scores 5.5, making your Silestone worktop much harder than your knives!

The word unique is often bandied about, but baked into the resin is Silestone’s patented antibacterial formula, derived from silver ions, actively killing bacteria and germs. Silestone is the only worktop with this feature, making it truly unique and eminently suitable for kitchens, food industry and health industry.

The quality of Silestone worktops is backed by two levels of protection, a 10 year warranty against product defects and also a 10 year limited “installed” warranty.

In which thickness is Silestone available?

For various applications and cost considerations, Silestone is manufactured in sheets of 12mm, 20 mm and 30 mm, providing a slab thickness for virtually any application, in small and large kitchens or other domestic or commercial areas where ultra-luxurious worktops are required.

Because of its remarkable strength, flexibility and resilience, Silestone can be used on particularly large surfaces. Various techniques are employed to further support and strengthen Silestone worktops, countertops or vertical applications stretching over long spans, and undermounting sinks and basins, without detracting from the classiness of Silestone.

Silestone is available in widths of 132 Cm, 140 cm and 305 cm.

Is Silestone only available as sheets?

Because Silestone can be formed and shaped, it is moulded into integrated single or double basins, sinks, accessories, end details, upstands, downturns, splashbacks, fixtures, fittings, decorations, etc. almost perfectly matching the colour and patterns of your worktops.

Silestone also manufactures floor and wall tiles to complement the opulence of a Silestone kitchen worktop with tis complete range of accessories.

How many different colours are available for Silestone worktops?

The Silestone colour range is constantly adapted to give better choices and versatility and with currently more than 60 colours, in combination with other materials, allow for an almost unlimited working palette.

For easy reference, Bluestone have also divided the colours into price bands.

Because Silestone is essentially made from natural minerals, slight variations of colour and pattern will be discerned from one sheet to the next. Rather than detract from the beauty of the worktops, this adds that additional natural aesthetic appeal.

How are Silestone worktops joined to create harmony and a seamless appearance?

To minimise wastage and for maximum strength, corner joints and butt end joints are usually square rather than mitred. They are smoothed and joined with specially formulated colour coordinated adhesives, silicone caulking and a heat process that make joints almost imperceptible, giving the appearance of a solid, seamless design and no crevices where dirt can accumulate.

Cutouts and corners are rounded and polished smooth and edges and to finish the worktops off, end details, upstands and downturns are available in a wide variety of shapes and designs.

Provision is made for clearances to allow for thermal expansion and contraction. This avoids cracks showing later.

When should I not use Silestone?

In the first instance, one should not use Silestone when common sense tells you it is not safe. For instance, if it might be too heavy to be properly and safely supported, if moisture could be trapped behind it and damage the structure behind, above or below it, or when it will be exposed to strong corrosive chemicals or acids for prolonged periods.

Typical examples would be when the wall or masonry construction is not strong enough to support its weight.

Because Silestone has to be cut with special blades that reduce heat, it may not be possible, or advisable to use it in areas that require further or later cutting after installation.

Silestone can withstand high temperatures, but in extreme conditions, heat shields or hot pads should be used to protect it.

Silestone is non-porous and resistant to stains, so chemicals will not be absorbed, but corrosive chemicals or acids will damage the surface. Of course the duration of contact will determine the extent of damage.

Silestone should only be fabricated and installed by authorised professional fabricators, such as Bluestone. It is not suitable for amateurs.

When surfaces are required that can easily be repaired, it might be advisable to consider high quality Solid surface worktops, such as Corian, Diore, Hanex or HiMacs.

Chemicals to Avoid

Although Silestone is highly resistant to chemicals and because they cannot penetrate the surface, it is nevertheless advisable to avoid unnecessary exposure of your Silestone surface to strong chemicals and solvents.

Items to avoid include:

- Nail polish remover, permanent markers or inks, oil soaps, and furniture cleaners or paint strippers that contain trichloroethane or methylene chloride.

- Chemicals with high alkaline/PH levels, such as oven cleaners.

- Products containing oils or powders may leave a residue.

- Repetitive use of abrasive scrubs and cleaners may dull Silestone’s finish.

- Oven/grill cleaner may discolour Silestone

- Repetitive and/or prolonged exposure to extreme heat may damage Silestone’s finish

Technical data

A sample of the chemical resistance of Silestone. These chemicals show no reaction for test periods of up to 16 hours:

- Acetic acid (10%); Acetone; Aromatic Ammonia; Ball point pen ink

- Household bleach; Benzene; Blood; Dry bond dental adhesive

- Ethyl acetate; food colouring, gasoline, ketchup (tomato sauce); tea

- Tincture of iodine; uric acid, vinegar, hydrogen peroxide

Performance properties of Silestone

- Density: 2.138 X103 Kg/m3

- Flexural (bending) strength: 78.9 N/mm2

- Tensile strength: 38.74 N/mm2

- Resistance to impact: 36cm/3.5J

- Abrasive Index: 65

Surfaces offering versatility & endless possibilities

Recent Posts

Specifying Diore Terrazzo: sustainable worktops

Your Content Goes Here In a built environment increasingly shaped by sustainability and lifecycle thinking, material selection matters more than ever. Architects, designers, and contractors are under growing pressure to specify [...]

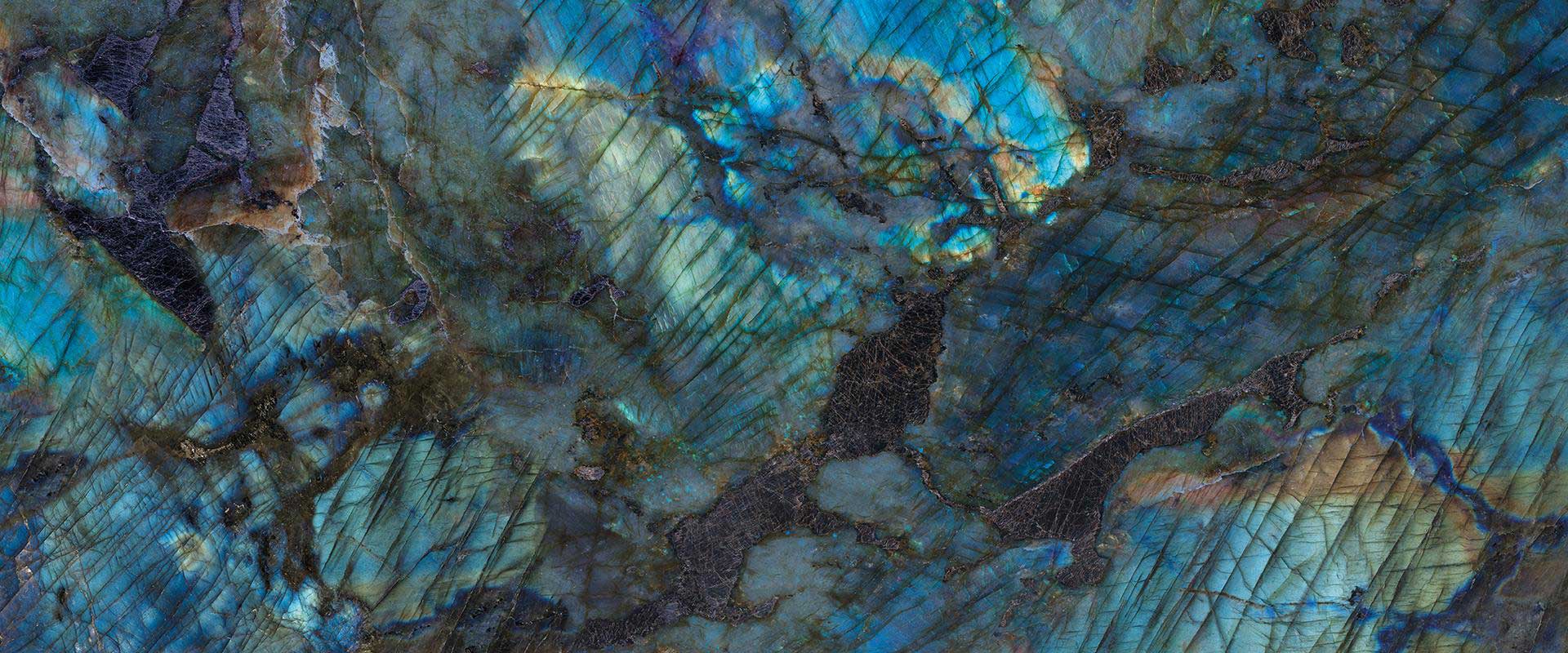

Diore Porcelain Illuminati

Seeing is believing...Introducing Diore Porcelain Illuminati: The illusion of Luminous StoneExperience the captivating beauty of Diore Porcelain Illuminati, a revolutionary surface collection that creates the illusion of natural luminosity. Designed to mimic the mesmerizing glow [...]

Caesarstone Expands Product Range with Porcelain Worktops

Your Content Goes Here Caesarstone, a global leader in premium surfaces, has recently broadened its product offering by introducing a new line of porcelain worktops. Known for its high-quality quartz [...]

Compac Terrazzo – High Performance Stone (HPS)

Your Content Goes Here COMPAC, the Spanish company specialising in the manufacture and distribution of quartz surfaces, has launched a revolutionary new material: Terrazzo High Performance Stone (HPS). This new material has been developed to [...]

Dekton Onirika, the latest collection from Cosentino

This stunning collection provides a flexible and inventive selection of ultra compact surfaces, empowering architects and designers to explore their imagination and transform their visions into reality Dekton®, the top ultra-compact brand by Cosentino, [...]

What is a Hanex worktop?

Hanex® is the registered international brand name for a premium range of acrylic solid surface material.66% natural stone, known as Alumina Trihydrate, is pulverised and blended with 34% acrylic polymer resins [...]