Installation of Silestone

What is Silestone?

Silestone is Cosentino’s registered trade name of the world’s leading quartz worktops, used in kitchens and bathrooms as well as for wall and floor cladding and furniture. The quality of Silestone is backed by more than 70 years’ experience and a written warranty.

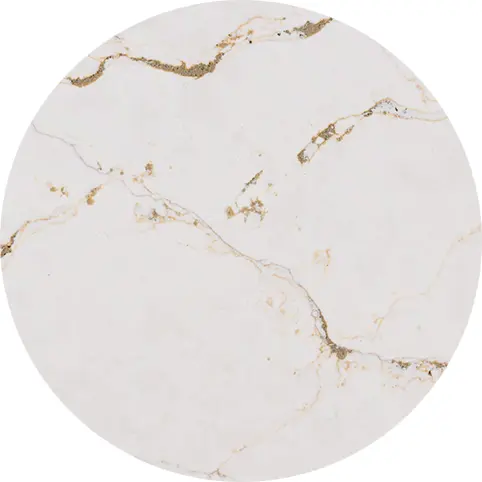

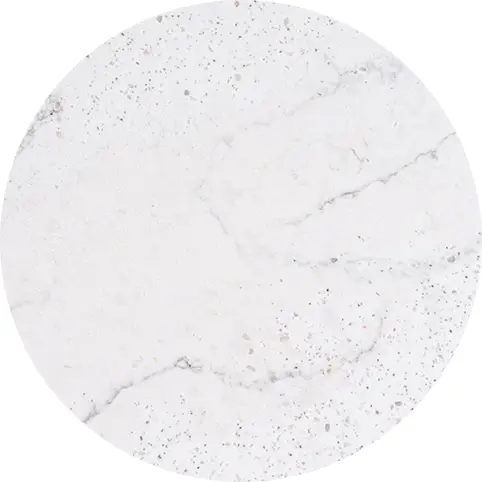

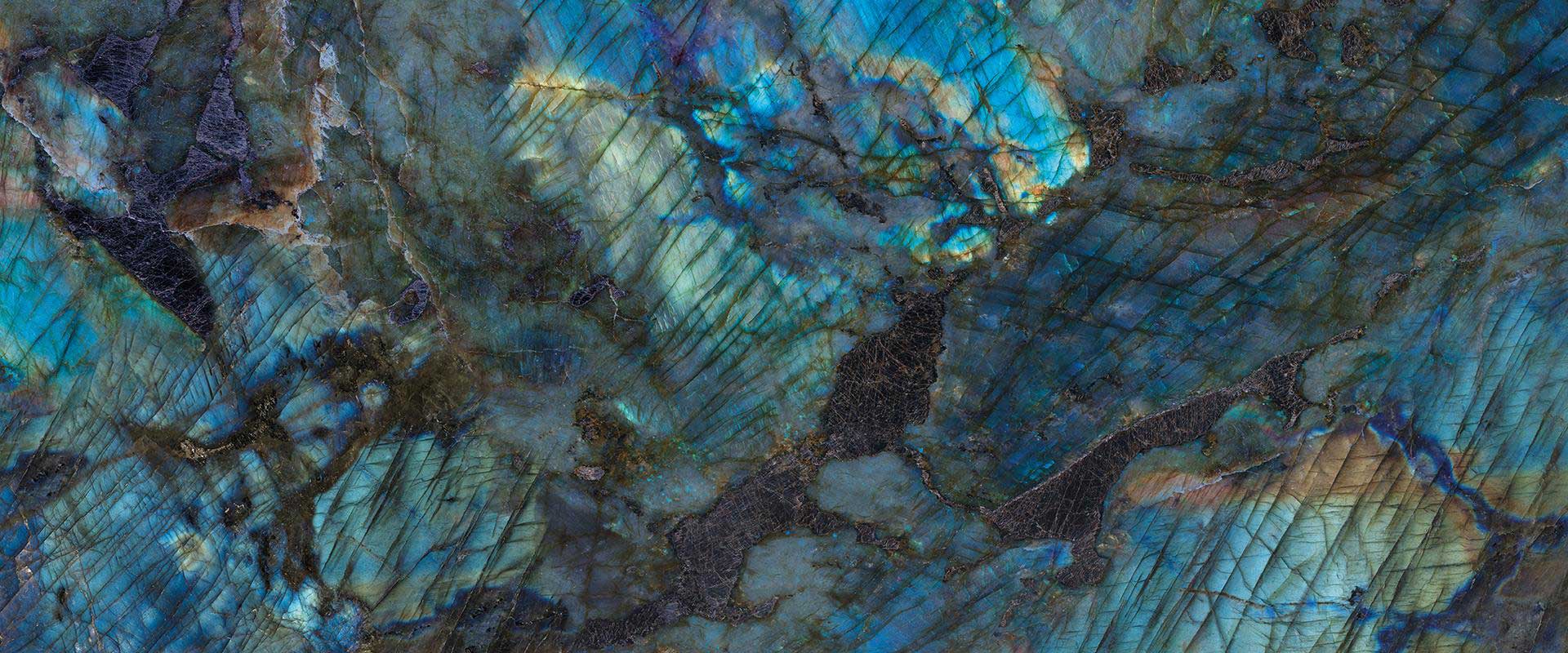

The dazzling appearance of natural quartz is reminiscent of diamonds and provide an elegance, sophistication and luxuriousness unsurpassed by any other worktop material.

Manufactured from 94% natural quartz, Silestone is extraordinarily hard, durable, resilient and attractive, with active anti-bacterial protection for the best possible hygiene. Quartz is completely natural crystallised silicon dioxide. It is usually white or transparent, but during its formation, several materials create different colours. Silestone is re-engineered stone created by pulverising the quartz and blending in the desired colours and binding resins, whereafter it is recreated through a special process using high heat and pressure.

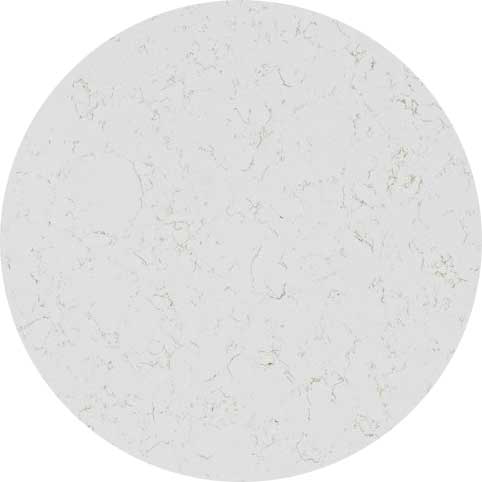

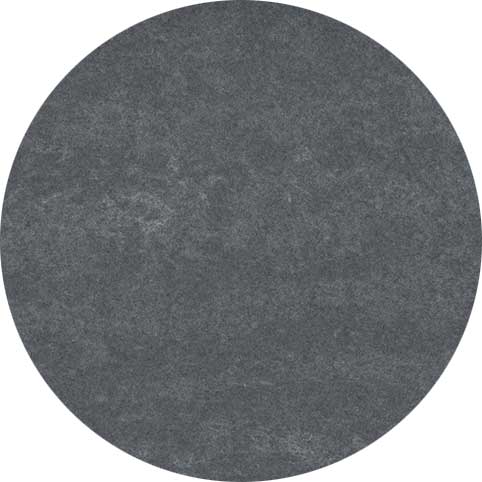

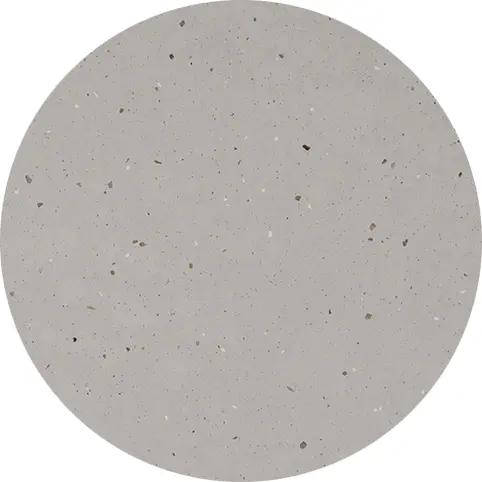

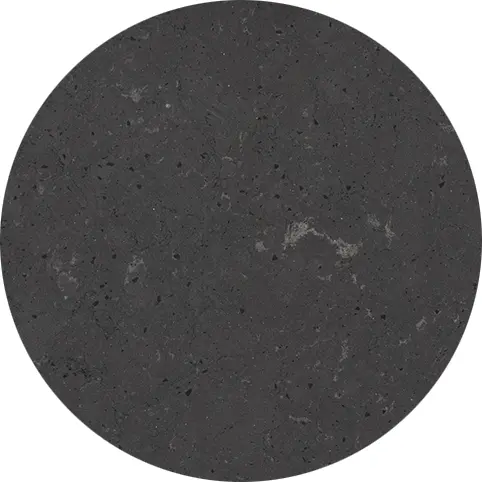

The inspiring variety of 60 different quartz colours and shades, in polished, leather and volcano finishes present infinite decorative possibilities in a variety of slab sizes and thickness. Silestone has a unique range of integrated sinks and accessories to create a sensational cohesive appearance.

Silestone is the smart choice for homeowners, contractors, developers and decorators as it delivers both unique beauty and extreme durability.

How do you install Silestone?

Silestone is a professional product and installation is best left to professionals. Bluestone is the leading fabricator of Silestone worktops in the UK and installation is done by approved professionally trained and skilled contractors.

The following guidelines are adhered to by professional installers:

Selection of slabs

Each slab is carefully selected to ensure matching tones and expertly polished edges. Each slab is individually identified and is correctly stored and securely transported on its edge.

Templating

Accurate templates are first created by means of high precision digital measuring and cutting to ensure a perfect fit for each piece, even along irregular wall surfaces or corners that are not perfectly square.

Area preparation

Cabinet or supporting structure levels, electrical and gas outlets, opening and closing of windows and doors, appliances and any other factor that might affect the installation is carefully checked before fabrication and installation.

Cutting

Silestone quartz worktops is one of the hardest materials known to man, surpassed only by diamonds, sapphire and topaz. Thus it requires special tools and cutting methods.

Onsite cutting likewise requires specialised equipment and great expertise.

Joints

Joint positions are determined during the templating process to ensure supreme elegance, strength and efficient design. Seamless joints ensure perfect hygiene and professional appearance.

Silestone joints are finished with a small ariss to the top edge, to which silicon sealant is applied to prevent water ingression and allowing for thermal expansion, which is about 1mm per metre of worktop.

If there is a backsplash, a small gap is left between the backsplash and the wall, which is filled with silicone sealant. If there is no backsplash, the back edge should be adhered to the wall.

Overhangs and supports

Overhangs extending more than 300 mm must be supported.

Sizes and thickness

For different applications, Silestone is available in slabs of:

- 3040 mm X 1380 mm; and

- 3270 mm X 1560 mm

Slabs are manufactured in three different thicknesses: 12mm; 20mm and 30mm

Sink installation

Both top-mount and under-mount sinks are available.

Integrated sinks are installed to the underside of the worktops. Adhesive or staples are used as reinforcement to attach the sink.

Surfaces offering versatility & endless possibilities

Recent Posts

Specifying Diore Terrazzo: sustainable worktops

Your Content Goes Here In a built environment increasingly shaped by sustainability and lifecycle thinking, material selection matters more than ever. Architects, designers, and contractors are under growing pressure to specify [...]

Diore Porcelain Illuminati

Seeing is believing...Introducing Diore Porcelain Illuminati: The illusion of Luminous StoneExperience the captivating beauty of Diore Porcelain Illuminati, a revolutionary surface collection that creates the illusion of natural luminosity. Designed to mimic the mesmerizing glow [...]

Caesarstone Expands Product Range with Porcelain Worktops

Your Content Goes Here Caesarstone, a global leader in premium surfaces, has recently broadened its product offering by introducing a new line of porcelain worktops. Known for its high-quality quartz [...]

Compac Terrazzo – High Performance Stone (HPS)

Your Content Goes Here COMPAC, the Spanish company specialising in the manufacture and distribution of quartz surfaces, has launched a revolutionary new material: Terrazzo High Performance Stone (HPS). This new material has been developed to [...]

Dekton Onirika, the latest collection from Cosentino

This stunning collection provides a flexible and inventive selection of ultra compact surfaces, empowering architects and designers to explore their imagination and transform their visions into reality Dekton®, the top ultra-compact brand by Cosentino, [...]

What is a Hanex worktop?

Hanex® is the registered international brand name for a premium range of acrylic solid surface material.66% natural stone, known as Alumina Trihydrate, is pulverised and blended with 34% acrylic polymer resins [...]