Solid Surfaces – Design Details

Solid Surface Worktops

Our solid surface worktops look sophisticated and elegant, and because they are so versatile can suit a variety of different designs whether that be traditional or a more contemporary style. The worktops are produced through a very special process, which means that they can be shaped, joined and formed into a variety of different shapes and designs, for numerous uses. The material can also be engraved, and amazing effects can be created from translucent colours. This means that you can create a highly personalised appearance for your worktop.

Here are some of the most popular design choices

Edge Details

>80mm

All internal profile edges must have a radius of at least 80mm. Thermoforming to achieve a smaller radius can result in “bleaching” of the colour and a visible laminating process is required.

- Bullnose

- Double Pencil

- Double Round

- Drip Groove

- Inlay

- Sharknose

- Single Bevel

- Single Imperial

- Single Ovolo

- Single Pencil

- Single Round

- Square

- Waterfall

Return Ends

- Angled Return

- Break Front

- Corner

- Curved

- Double Notch

- Double Radius

- External Splay

- Full Return

- Part Return

- Single Radius

- Splayed Break Front

- Triple Notch

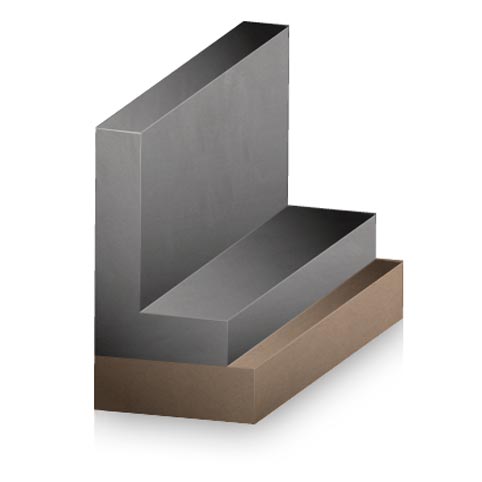

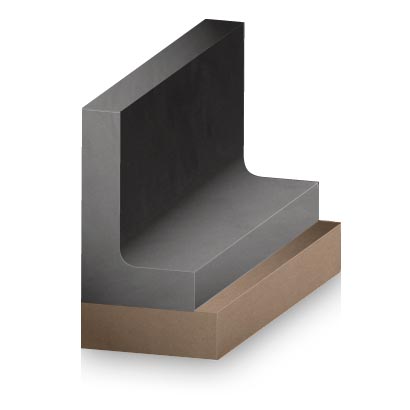

Square & Coved Upstands

Square upstands are fixed on site, with special glue or silicone. Coved upstands are manufactured and fixed in the factory.

Upstands are manufactured in a straight line and any imperfections and large variations in the wall profile will leave gaps that need to be filled with decorators caulk. Plastering or tiling should therefore be completed after the worktops have been installed.

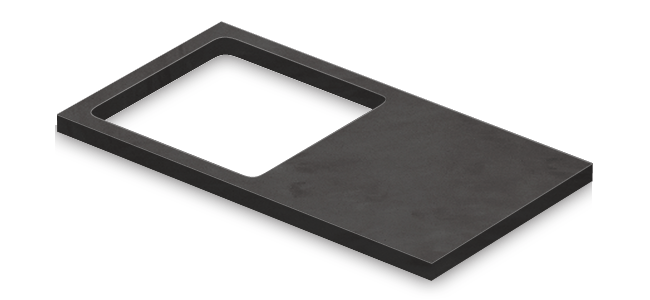

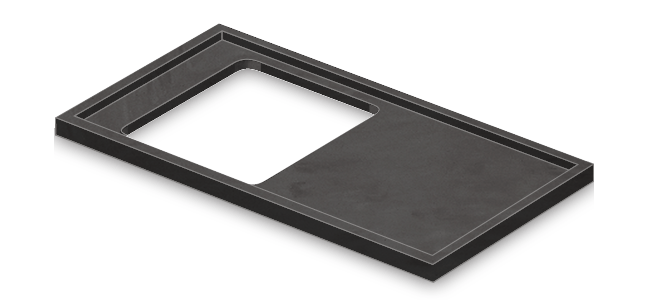

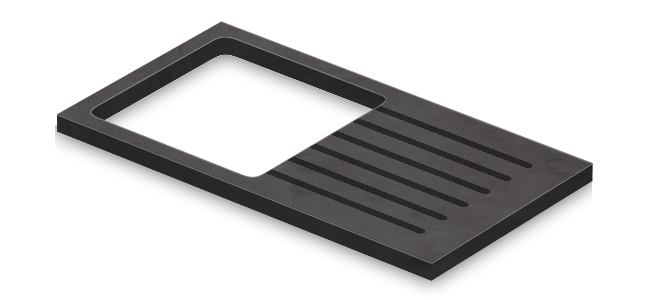

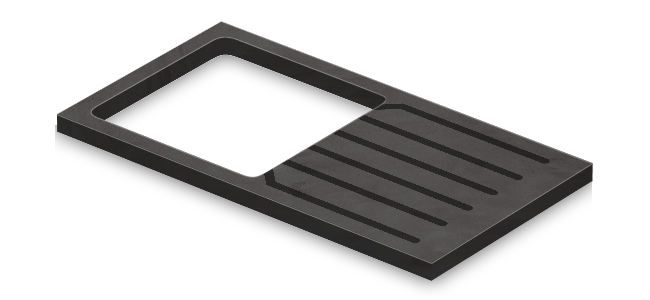

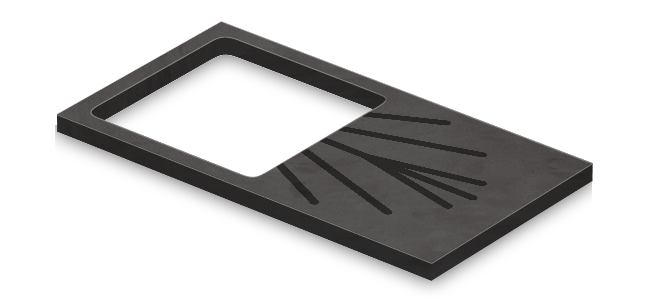

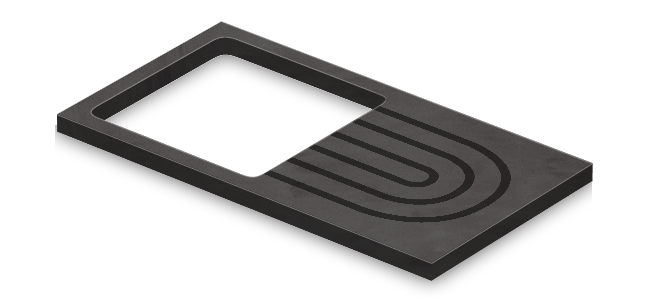

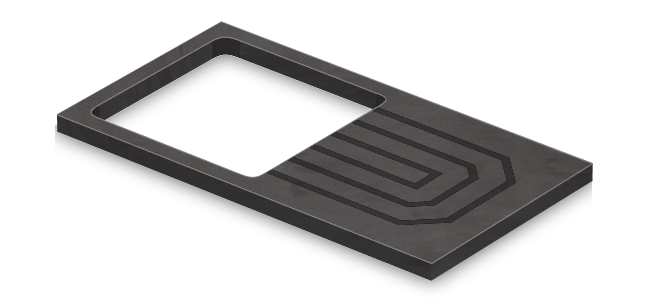

Cutouts & Drainer Grooves

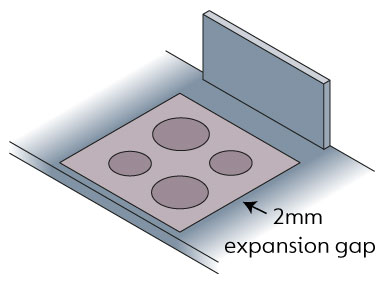

Hobs are installed according to a patented high-strength cutout method, integrating the hobs and worktops according to specified guidelines.

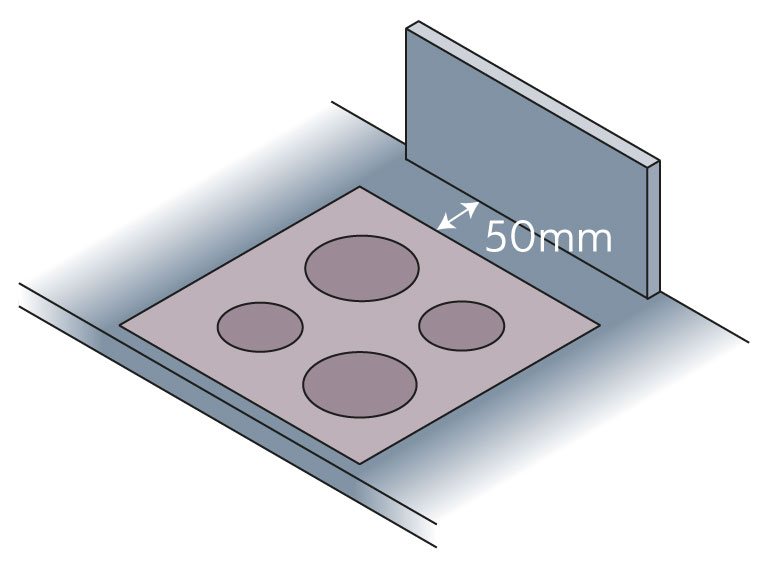

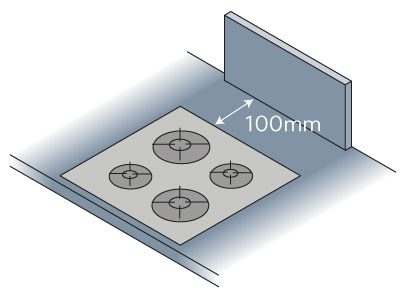

Splash backs or wall cladding are installed with a minimum 50mm gap behind an electric hob and a minimum 100mm gap behind a gas hob. There must also be a minimum 50mm gap from the cutout to the front of the worktop. To accommodate these requirements, it is sometimes necessary to widen the worktop to what is called a “breakfront.”

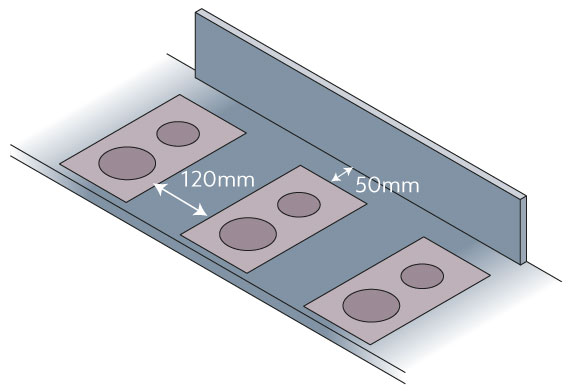

- Sink cutouts are placed a minimum 50mm from the worktop front edge

- A minimum of 120mm is required between two hob cutouts

- A minimum of 100mm is required between hob and sink cutouts

- A minimum of 70mm is required between two sink cutouts

- If a waste disposal unit is fitted to an undermounted sink after installation, additional support will be required, otherwise your warranty may be invalidated

Technical Information

Care and Maintenance

Bluestone offer a Care and Maintenance Kit which has been developed to offer the customer everything they need to keep their worktops looking good for years to come.

Scratches

Solid surface worktops are highly scratch resistant but not scratch proof and the surface must be protected by chopping or cutting boards. Dark, heavily pigmented colours will show scratches, dust and ordinary wear and tear more readily than lighter, textured forms.

Bluestone offer a Care and Maintenance Kit which has been developed to offer the customer everything they need to keep their worktops looking good for years to come.

Staining

Solid Surface worktops are resistant but care must be taken to clean the worktops down. Solid surface worktops are non-porous and will not absorb liquids, but it is still possible that grease, wine, coffee, nicotine, fruit juices and other strongly coloured substances can stain the surface if not properly protected or if the spills are not cleaned up immediately.

Hygienic

Solid Surface worktops is naturally hygienic as it is non-porous and the seamless joints do not harbour germs

Handling

For installation of worktops weighing above 120kg, you will need to supply additional labour at no cost to Bluestone. Every additional 75kg requires an extra person to assist with lifting.

Repairable

Solid surface worktops can be repaired. For minor scratches and marks, using an ordinary abrasive cleaner and a scouring pad the surface may be fully restored to its original appearance. For more extensive damage, Bluestone provides a special kit and beyond that, our specialist team can do repairs.

Because solid surface worktops are fabricated to give a seamless appearance, it is also possible to install sinks and bowls from the same materials for a smooth and elegant finish.

Because solid surface worktops are fabricated to give a seamless appearance, it is also possible to install sinks and bowls from the same materials for a smooth and elegant finish.