Granite Design Details & Technical Information

Granite Worktops Fabrication Process

Granite is one of the hardest natural rocks on earth, rating 7 on Mohs hardness scale, but with the proper care, can be turned into one of the most beautiful surfaces. Bluestone uses state-of-the art technology to lovingly cut and polish natural slabs to create a magnificent and timeless worktop that is truly unique, in that no two pieces of granite look exactly the same.

Here are some of the most popular design choices

Edge Details

- Square

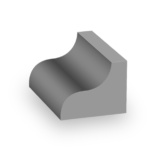

- Ogee

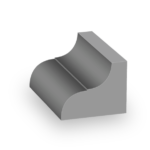

- Type O

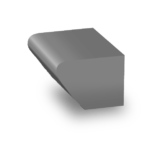

- Shark Nose

- Imperial

- Double Pencil

- Single Pencil

- Double Bevel

- Single Bevel

- Bullnose

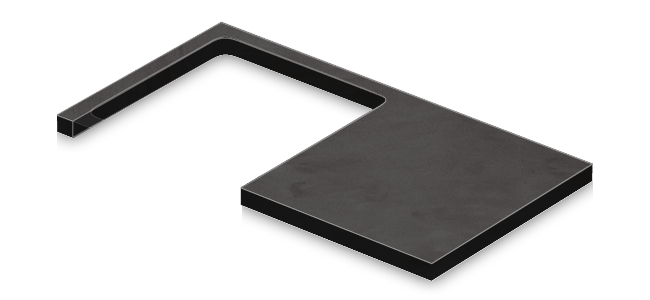

Return Ends

- Angled Return

- Break Front

- Corner

- Curved

- Double Notch

- Double Radius

- External Splay

- Full Return

- Part Return

- Single Radius

- Splayed Break Front

- Triple Notch

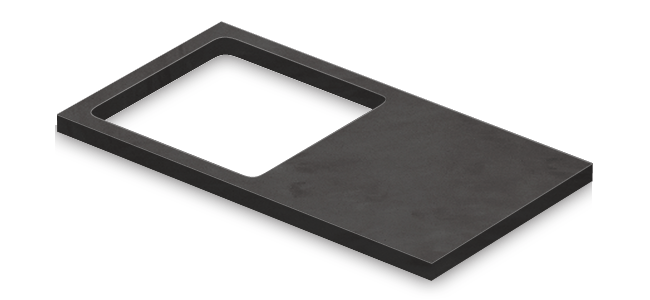

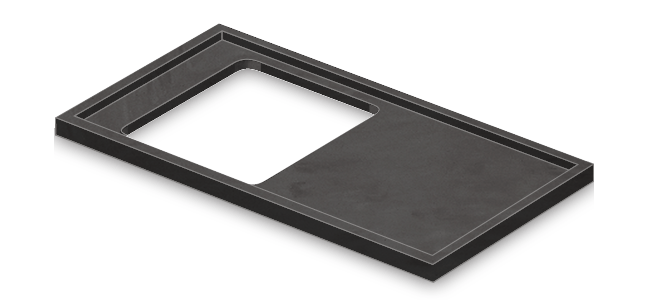

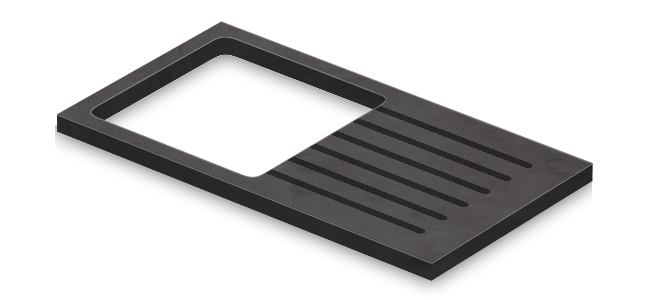

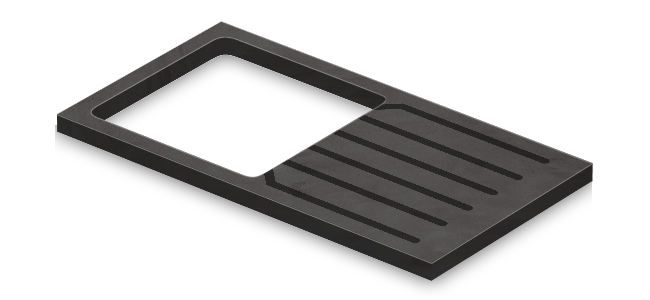

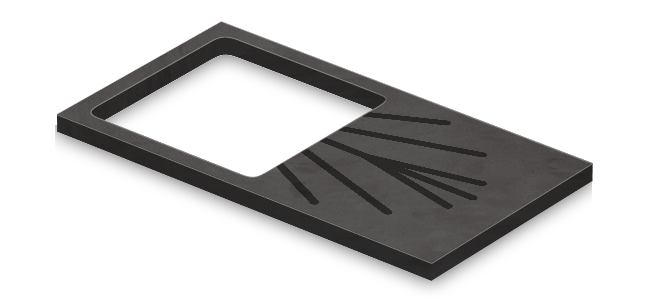

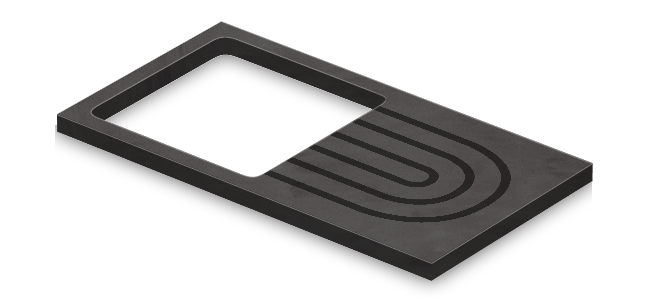

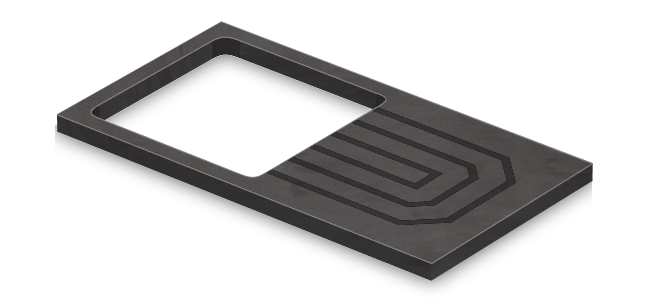

Cutouts & Drainer Grooves

Hobs are installed according to a patented high-strength cutout method, integrating the hobs and worktops according to specified guidelines.

Splash backs or wall cladding are installed with a minimum 50mm gap behind an electric hob and a minimum 100mm gap behind a gas hob. There must also be a minimum 50mm gap from the cutout to the front of the worktop. To accommodate these requirements, it is sometimes necessary to widen the worktop to what is called a “breakfront.”

- Sink cutouts are placed a minimum 50mm from the worktop front edge

- A minimum of 120mm is required between two hob cutouts

- A minimum of 100mm is required between hob and sink cutouts

- A minimum of 70mm is required between two sink cutouts

- If a waste disposal unit is fitted to an undermounted sink after installation, additional support will be required, otherwise your warranty may be invalidated

Technical Information

Care and Maintenance

Bluestone offer a Care and Maintenance Kit which has been developed to offer the customer everything they need to keep their worktops looking good for years to come.

Scratches

Granite is highly scratch resistant but not scratch proof. Slate, marble and limestone are much softer than granite and greater care must be taken to avoid scratches to the surfaces.

Staining

The stone will be sealed in the factory but it is possible to stain it with such things as wine or grease. It is recommended that the worktop must be re-sealed every 6 months to help reduce the risk of any damage to your worktops. Bluestone sell care & maintenance kits which clean, seal, and maintain your granite worktops to the very highest standard.

Hygienic

Certified and approved for direct contact with food.

Handling

For installation of worktops weighing above 120kg, you will need to supply additional labour at no cost to Bluestone. Every additional 75kg requires an extra person to assist with lifting.